India’s armed forces are rebalancing to the north. Infrastructure development will continue. Good news. Across the LAC, China is ‘solidifying Tibet’. Hereafter, the areas adjoining the LAC will see elevated troop levels even if there are no hostilities. The number of troops to be maintained permanently in extreme high altitudes will nearly double (including IAF personnel). It also means an increased logistical load year on year. In these areas, energy is required to power battlefield systems (weapons, surveillance platforms, networks), transportation and most importantly for human sustenance. High altitude operational areas and battlefields are energy guzzlers due to rarefied atmospheres, lack of oxygen and inefficient engines. Energy requirement of the battlefield will keep increasing with modernisation. Till now the single-point answer to meeting energy requirements in high-altitude areas has been fossil fuels—kerosene, petrol and diesel. Not anymore.

Advanced Winter Stocking: Presently an intricate and complex system is in place to ensure that the required fossil fuels are sent up from the plains through a time-tested procedure called the Advanced Winter Stocking. In this system, the complete requirement of energy for one year is stocked from plains in high altitude in about 3-4 months of the ‘Road Open’ period. It involves multiple legs, modes and transfers. It is a complicated, laborious, tenuous, and extremely expensive process. Environmental degradation is high. This will now have to be doubled. We are exacerbating a nightmarish and unsustainable process. The answer is to find energy in situ.

The High-Altitude Problem: The problem in High altitudes is that other energy options—Hydro, Solar or Wind are unreliable and available only for part of a year. Significantly, hydro and solar energy are inadequate in winter, when needed most. Continuing to burn fossil fuels is extravagantly costly and intensively polluting. To give an idea of cost. The landed cost of kerosene at any post in the Siachen was Rs2400/-, when a litre cost Rs 15, a decade back. That is a whopping 160 times increase. Today it should be around Rs 4,000 per litre. All posts in eastern Ladakh which have now been added are in that variety. Can we bear this burden hereafter at inflated costs? So, what do we do? Turn to technology. I got this idea when I was studying about energy requirements in space being met through the hydrogen—Fuel Cell system.

FUEL CELLS AND HYDROGEN SYSTEM

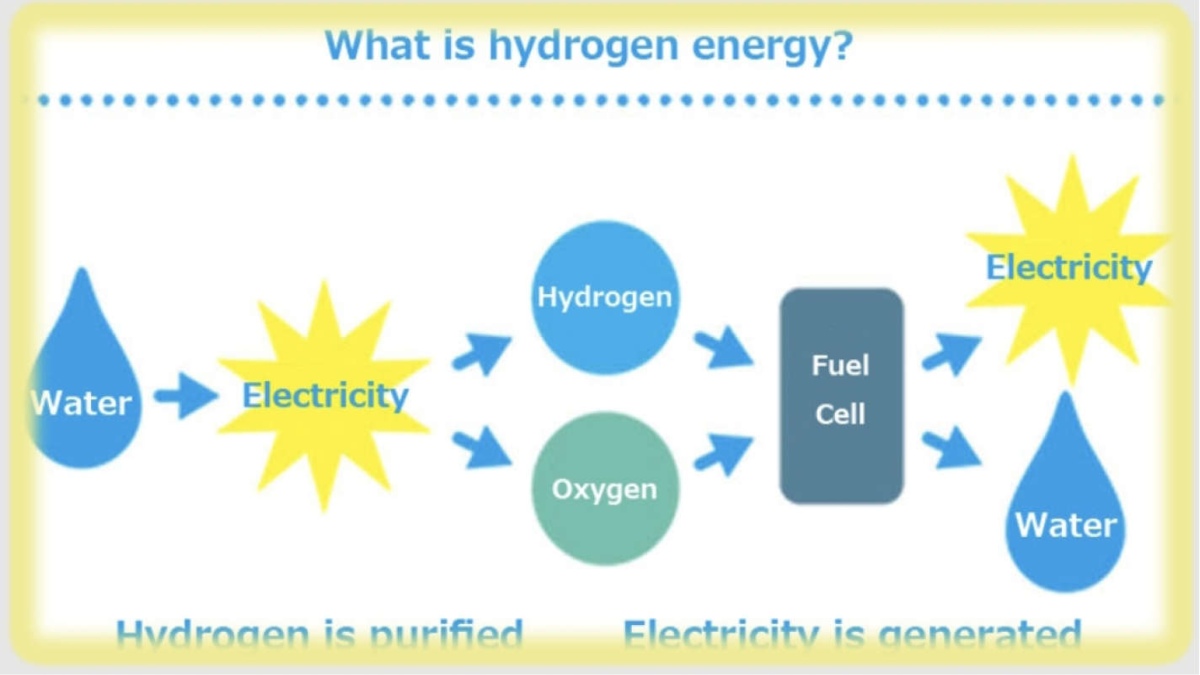

‘Oil of space’ in high altitude. Space applications need enormous energy which is created out of water, hydrogen and oxygen. In fact, water is called the ‘oil of space’. Simply put, hydrogen and oxygen are used in space to create energy. They are derived from water (which incidentally is not available in space). The entire business of lunar landings is all about the search for water; which is then converted into energy for further exploration and sustenance. Just think. High altitudes are as desolate as space but have water! Hence, we must exploit this resource and not look outside. I am convinced that since we have to deploy large numbers of troops in High altitudes and also be able to sustain people through development, the only way forward is to take a technological leap by using water for energy—Fuel Cells and the Hydrogen system. Let me elucidate this further.

Fuel Cells: Fuel cells can provide power for systems as large as a utility power station and as small as a laptop computer. A fuel cell combines hydrogen with oxygen to produce electrical power. It works similar to batteries, but never runs down or needs to be recharged. It has a cathode and an anode separated by an electrolyte. In a fuel cell, the electrode is not consumed, and the cell can produce electricity as long as hydrogen and oxidizer levels are maintained. With hydrogen as fuel, heat and water are the only by-products. Fuel cells are of many types: proton-exchange-membrane fuel cells (PEMFCs), regenerative fuel cell (RFC) systems, alkaline fuel cells, direct methanol fuel cells (DMFC), phosphoric acid fuel cells (PAFC), molten carbonate fuel cells (MCFC) and solid-oxide fuel cells (SOFCs).They can run indefinitely, as long as they are supplied with a source of hydrogen and a source of oxygen (usually air).

Efficiency: Fuel cells are less efficient than electric batteries. However, present day fuel cells are comparable with internal combustion engines. IC engines convert fuel into kinetic energy at roughly 25% efficiency. A fuel cell, by contrast, can mix hydrogen with air to produce electricity at up to 60 % efficiency.

Hydrogen: Hydrogen can be produced cost-effectively through electrolysis by splitting water into its constituent hydrogen and oxygen atoms or from LNG. Currently only 2% of the world hydrogen production is from water electrolysis. 98% is produced from natural gas. We have to focus on electrolysis. Electrolytically produced hydrogen is presently costly. It will need initial investment in hydrogen production and distribution infrastructure. The scarcity of infrastructure is the largest obstacle to the adoption of hydrogen technology. This process is getting cheaper with time.

International Efforts: The Toyota Mirai, the most popular Fuel Cell Electric Vehicle (FCEV), sells world-wide. UAE’s first hydrogen station has been opened by Toyota. In Japan, 100 refuelling stations have already been established, and the government aims to have 800,000 FCEVs on the road by 2030. Cost of Hydrogen is expected to reduce by 90% by 2050. Hydrogen technology is being contemplated for a range transport market segments and other applications. Hydrogen trials have been conducted on everything from public buses and forklifts to trains, planes and boats. In Europe, the ‘EU Turbines’ group was to make their gas turbines run with 20% hydrogen gas initially (it was to be completed by 2020). They want to develop turbine technology to allow all manufactured units to run, or be retrofitted to run, on 100% hydrogen gas, and be carbon-neutral, by 2030. All major gas turbine manufacturers are currently developing gas turbines that could combust 100% hydrogen, for power applications as a decarbonised alternative to natural gas. These are just examples to highlight international efforts.

Falling Cost of Hydrogen Systems: The cost of hydrogen is falling due to improvements in water electrolysis and hydrogen fuel cell technology. The Paris-based International Energy Agency expects the cost of producing hydrogen to fall by a further 30% by 2030. It might fall even faster. Since 2010, the cost of electrolysis has fallen about 60% (from between $10/kg and $15/kg hydrogen to as low as $4/kg). By 2030 costs could fall another 60%. As investment in hydrogen infrastructure grows, net costs will continue to fall. However, hydrogen will only be “relevant in regions constrained in renewables potential and situations where alternatives like fossil fuels are not an option.” This is a ready-made high-altitude scenario. For an assumed import price of $3/kg of hydrogen (international average cost), power produced from hydrogen turbines could cost about $140/MWh. In comparison, Lazard’s November 2019 levelised cost of energy (LCOE) analysis suggests unsubsidized natural gas combined cycle generation today costs between $44/MWh and $68/MWh (approx. three times costly).

Strengths and Challenges: Hydrogen and fuel cell systems are very reliable, quite in operation (no moving parts) and need very little maintenance. They are modular and scalable. They occupy less space when compared to wind or solar systems, and can be sited both outdoors and indoors. Fuel cells are pollution free when run on pure hydrogen. They are more efficient than combustion engines. Fuel cells can be refuelled, which is faster than recharging. A fuel cell gives more bang per energy buck than a similarly-sized battery. Fuel cell systems are lighter even taking into account hydrogen storage. The main challenges of fuel cells are price, cost of producing hydrogen and need for pure fuels. Hydrogen is difficult to store. It must be heavily compressed in order to fit into a practical container. Hydrogen gas requires high-pressure fibre-composite tanks. Liquid Hydrogen requires keeping its temperature down to cryogenic levels. However if the system is in a ‘consume as you produce’ mode the costs will reduce. Hydrogen is mass produced in the US. The technology has been around for over half a century.

We need to think out of the box: Technologically and practically to solve the exponentially increasing battlefield energy requirements. The current system will be an unsustainable nightmare. If we think of ‘High Altitudes’ as ‘Space’, the answer lies in water! Compare costs. The current cost of fuel in high altitudes should be around 60-70 times on an average at the delivery point. Hydrogen based energy would be far cheaper and less complex even now including infrastructure. The cost of fossil fuels keeps inflating whereas the hydrogen economy is deflating. In the long term, the pollution free, fuel cell-hydrogen system wins hands down. The technology is established. It needs to be adapted, It also needs a multi-agency approach at national levels since there are wider implications than just for the Armed Forces. From a national perspective this should be a civil military fusion project led by the Armed forces. Do we have a choice in not following this route? Of course, we have. We can remain primitive.

It is my recommendation that an inter-departmental pilot project be started in Leh under the aegis of the Army. In about a year or so we will have gained enough experience to scale it up. It is also cautioned that fuel cells cannot be deployed everywhere and are not the ultimate solution. We have to eventually have to look at an energy mix in which fuel cell energy share is expanding. Use of some fossil fuels and naturally renewable energy systems will continue. Most importantly we need to start somewhere.

HOPE

This is not a flight of fancy. I do hope someone with sense in the decision matrix reads it and takes action.

MY FEAR

The Chinese will read this and pick up the idea. They will implement it while we keep humping kerosene-like cavemen to Siachen and revel in burning it in soot filled bukharis which will choke our lungs and continue to degrade our environment. The day Global Times puts out a video showing off their fuel cell deployment ahead of us will be a sad day for me.

Lt Gen P.R. Shankar was India’s DG Artillery. He is highly decorated and qualified with vast operational experience. He contributed significantly to the modernisation and indigenization of Artillery. He is now a Professor in the Aerospace Dept of IIT Madras and is involved in applied research for defence technology. His other articles can be read on www.gunnersshot.com.